Train Depot

Futuristic state of the art technology, DX LINE

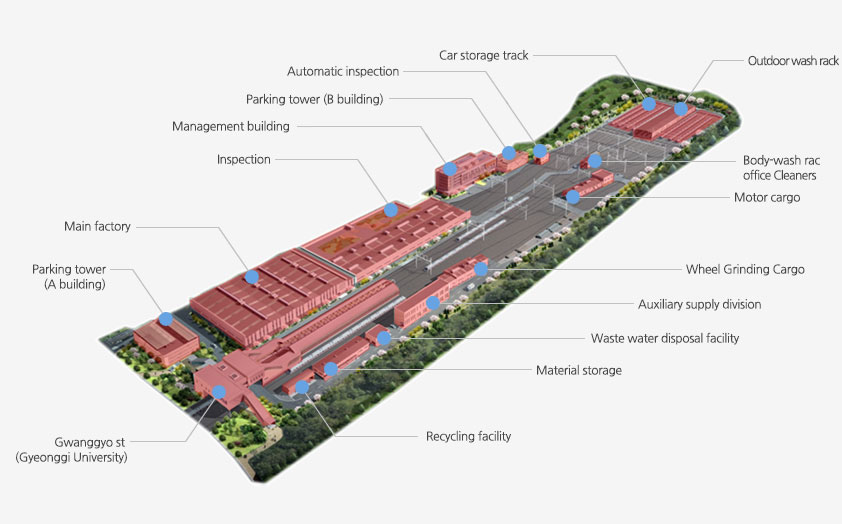

- Gwanggyo Train Depot

-

01 Train Depot(Gwanggyo)

Train Depot (Gwanggyo) table Train depot Plottage 125,125 ㎡ Construction area 27,245 ㎡ Gross floor area (GFA) 43,636 ㎡ Facility Size 15 Buildings including management Building

Train Depot table division Track status note system 22 Car storage track Car storage track 14 - Car inspection track Day / month inspection 2 - Input / travel line 2 - Cleaning ship Daily cleaning line 1 - Wide cleaning line 1 - PIT lines 1 - Commissioning line Line-site commissioning 1 958m 02 Affiliated -building Description

□ Motor Cargo

Motor Cargo table division Construction area Construction area 874.89㎡ Gross floor area (GFA) 1,109.16㎡ Number of floors Ground floor 2 Building structure SRC structure □ Wheel grinding cargo

A place composed of the pit and office with supplies installed to grind the wheel turning when the wheels are on a worn condition and have defects.

Wheel turning table division Construction area Construction area 564.10㎡ Construction area 564.10㎡ Number of floors Ground floor 1 Number of floors SRC structure □ Auto scanner

Inspect all vehicles and wheels returned to the base after being operated

auto scanner table division Construction area Construction area 128.16㎡ Gross floor area (GFA) 124.64㎡ Number of floors Ground floor 1 Building structure RC structure □ Auto-washing

A facility where incoming trains after the operation are washed automatically

auto-washing table division Construction area Construction area 202.26㎡ Gross floor area (GFA) 202.26㎡ Number of floors Ground floor 1 Number of floors RC+SRC structure □ Outdoor washing

A facility washing the train within the car storage track

outdoor washing table division Construction area Construction area 2,567.57㎡ Gross floor area (GFA) 2,567.57㎡ Number of floors Ground floor 1 Building structure S structure □ Auxiliary division power supply distributor

Placed on a large section of train lines where electric power loads improves efficiency, install shutters by considering the equipment brought.

Auxiliary supply division table division Construction area Construction area 478.19㎡ Gross floor area (GFA) 951.00㎡ Number of floors Ground floor 2 Building structure RC structure □ Storage

Install a deck to load and unload, as well as plan forklift ramp

Secure the space for work and large vans to be parkedstore room tavble division Construction area Construction area 439.97㎡ Gross floor area (GFA) 439.97㎡ Gross floor area (GFA) Ground floor 1 Building structure S structure □ Waste Water disposal facility

A waste water disposal facility within the station

Water disposal facility: Public Works

Ground care facilities: construction workWaste Water disposal facility table division Construction area Construction area 203.66㎡ Gross floor area (GFA) 229.00㎡ Number of floors Underground floor 1, ground floor 1 Building structure RC structure □ Parking tower B

For a smooth parking within the station, the doorway for entrance-exit, and the ipsilateral comprehensive management should be installed separately. Parking Tower building B should install an ipsilateral comprehensive management.

parking tower B building table division Construction area Construction area 723.00㎡ Gross floor area (GFA) 2,561.15㎡ Number of floors Ground floor 4 Building structure SRC structure - Heavy Maintenance

-

Heavy Maintenance

In the maintenance center we maintain the vehicle on its best condition for the safe transport of the customers.

□ Main task by each vehicle

Maintenance

- Electricity / Break

- Inspects entry and out-going vehicles

- Supply parts (Panto, lightning arresters, etc.)

- Brakes (BOU, ECU etc.)

- Jumper connector

- Broadcast equipment

- Leveling valve

- Bogie

- Compose / Decompose balance

- Ultrasonic

- Wheel replacement

- Driving gear

- Tread / Parking brake system

- Lateral damper / Air spring

- Body / Rotator

- Entrance / Exit doors engine

- Line flow fan

- Traction motors

- Main air compressor

- Auxiliary air compressor

- Heat / Cooling equipment

- Electronic /

Commissioning - entry-outgoing vehicles inspection

- Main conversion device

- Auxiliary power unit

- Electronics disassembly, inspection

- EMU function tests

- Domestic / Line Commissioning

□ Status oftesting equipment

- - Washing Equipment : Truck Washing Machine and 14 others

- - Moving Equipment : Overhead crane and 20 others

- - InspectionEquipment : Long inspection machineryand 20 others

- - Testers : Tread brake tester and 37 others

- - Machine tool : Shelf upright tool and 22 others

□ Major inspection equipments

-

Washer

-

Bearing washer

-

Truck washing machine

-

Overhead crane

-

Tow truck

-

Turntable

-

Wheelset press

-

Wheel lathe

-

Upright Lathe

-

VVVF tester

-

Traction motor tester

-

SIV tester

- Light Maintenance

-

Light Maintenance

To ensure maintenance of the status and functions of the main parts

□ Daily maintenance: 3 days or when it reaches 1500km (7~9 reforms / 1 day)

EMU function check(visual measurement)

□ Monthly Maintenance is one every 3 months or when it reaches 450,000km (1 reform / 3 days)

Up / Down device inspection

Filters, lubricants, such as consumable items change